Application of black laser marking technology on aluminum

2022-06-08 | Technology Information

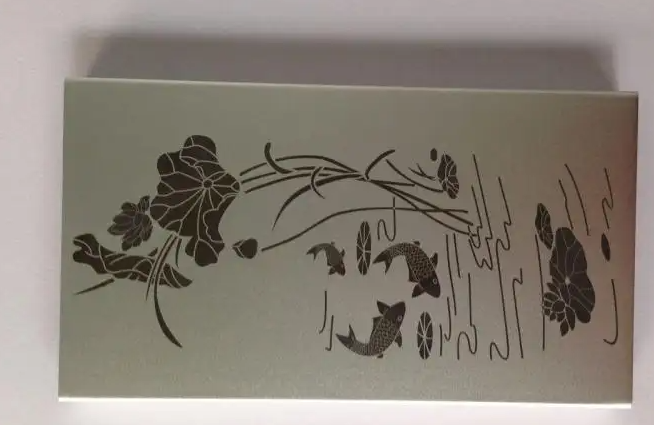

With the development of the aluminum industry, everyone's requirements for aluminum products are getting higher and higher. Do you want your products to be unparalleled in anti-counterfeiting capabilities? Do you want to improve product grade and brand sense and increase the added value of the product? Laser marking machine is fast and efficient in aluminum production, and the pattern effect produced by it is fine and beautiful, so it is very popular. In the application of laser aluminum, the most widespread and effective is laser black technology.

Laser aluminum blackening technology principle

Laser marking is a processing method that uses a high-energy-density laser to irradiate a workpiece, vaporize the surface material or change the color of the chemical reaction, leaving a permanent mark. The laser marking machine black technology is for anodized aluminum. Due to the Nano effect, the size of the oxide particles is nano-level after laser processing, so the light absorption performance of the substance is increased, so that visible light can be absorbed and reflected by the substance. There is very little visible light, so it is black to the naked eye.

Aluminum black application

Aluminum black is suitable for various aluminum alloy materials such as alumina, magnesium aluminum, etc., and its application is quite wide. The most common are iPad tablets, mobile phone back cover aluminum for logo and text blackening, and various mobile phone accessories, clocks, aluminum stamping, molds and other products for trademarks, logos, batches, etc.

Laser processing advantages

1. Permanent: The blackening effect will not fade due to the environmental relations such as touch, high and low temperature, acid and alkali.

2. Anti-counterfeiting: Laser blackening is a physical process. The marked information cannot be altered and has strong anti-counterfeiting properties.

3, low cost: laser black molding at one time, no auxiliary materials and a large number of manpower, low consumption.

Features and characteristics of aluminum black laser marking machine

Protect imported fiber laser window with original imported isolator to enhance stability and laser life;

The beam quality is good, the electro-optical conversion rate is high, and the processing speed is fast, which is 5-10 times that of the traditional laser marking machine;

No consumables, no maintenance required, long service life, small size, suitable for harsh environment work;

High reliability, maintenance-free, no chiller is required, completely air-cooled, easy to operate;

Simple operation, equipped with humanized operation software;

Excellent optical quality, high precision, suitable for fine work, suitable for all metals and some non-metals.

Related News

The new net red in the laser industry--Hand held laser welding machine

Hand held laser welding machine generally consists of laser, chiller, control software, laser welding head, optical fiber and other components.It has the advantages of small footprint, convenience, and strong functionality...

[Gathering Strength, Blossoming Youth] Day Trip to Heyuan

Relieve the pressure, release the passion, unite the team strength in the game, and bloom the charm of youth in the joy!

Medical atomizing sheet micro-hole laser marking machine, help your health

Air conditioner humidifiers, facial moisturizers, and hospital atomizers commonly used in our daily life, these products will have an atomizing film inside. This atomizing film has a large number of dense small holes. The size of these small holes is as well as The density directly determines the spray effect. Therefore, in order to achieve the best spray effect, it is necessary to choose the right drilling process.